40 high pressure processing labels

Benefits of HPP | hydrofreshhpp.com HPP uses cold pressure which does not damage the natural nutrients of the product like heat pasteurization can. Clean Label HPP allows manufacturers to eliminate chemicals and preservatives while maintaining freshness and taste. Extends Shelf Life PDF Further Processing and Labeling Inspection Course - Student Handout Label/Labeling . The term "label" means a display of written, printed, or graphic matter upon the immediate container of any article. The term "labeling" means all labels and other written, printed, or graphic matter upon any article or accompanying the article. These terms can be found in 21 . U.S.C. 601(o) and (p). Regulations and ...

High Pressure Processing (HPP) Services - Universal Pure High Pressure Processing (HPP) - sometimes called high pressure pascalization or cold pasteurization - is a science-based food safety and preservation method. HPP uses only cold water and extreme pressure to safely and naturally preserve food and beverage products.

High pressure processing labels

HIGHdegree Materials - Tags and Labels for Inventory ... - Polyonics Polyonics Offers High-Temperature Tags and Labels for Extreme Track and Trace Applications in Metals Processing Factories Westmoreland, NH, January 13, 2021 - Polyonics®, a leader in high temperature and harsh environment label and tag materials, announced today a new line of materials specially engineered to stand up to the punishing ... Pressure-sensitive adhesive technologies | Labels & Labeling Pressure-sensitive label adhesives successfully meet an enormous range of demands. They can provide a permanent bond or can be removable. ... That will, for sure, deliver higher shear values, but the downside is that the viscosity of the material becomes so high that processing equipment will no longer properly work. So there is a trade-off ... High Pressure Processing (HPP) | MCC Label MCC has created a label that can inform the consumer whether or not the product has been protected by HPP technology. Once activated by pressure, the check mark appears and the ink color change is irreversible. Key features Durable label that can actively verify that the product has undergone the pressurization process Possibility of high opacity

High pressure processing labels. Keeping Clean Labels Simple for Safer, Healthier Food Increasing the Shelf Life of Clean-Label Products. To increase the shelf life of the products in clean-label ingredients, several technologies have been employed. High-pressure processing (HPP) is a method of preserving packaged food products using extremely high pressure. What We Do - American Pasteurization Company APC works with every kind of product producer, from food industry veterans to entrepreneurs, to create a customized framework for food safety and brand equity protection unique to every product. Our Locations: Milwaukee Plant 2880 North 112th Street Building E Milwaukee, WI 53222 Sacramento Plant 2335 Del Monte St. West Sacramento, CA 95691 American Pasteurization Company American Pasteurization Company (APC) is the first company in the United States to offer High Pressure Processing (HPP) on a commercial tolling basis to the food manufacturing industry. HPP kills bacteria that can cause spoilage and food-borne illness, and greatly extends shelf life. Label Materials For High Pressure Processing | SheetLabels.com To reduce contamination in the packaging process, food or beverages that go through HPP are packed, sealed, and labeled before they go through high pressure processing. So, the product label, package, and the food or beverage item are all exposed to hydrostatic pressure of up to 600 MPa or 87,000 pis during HPP.

Beverage Preservation 101: Part II - BevSource High Pressure Processing (HPP) does not use heat. Instead, HPP applies a large amount of pressure to preserve the product. The product is packaged in a flexible container and put into a high-pressure chamber that applies as much as 87,000 pounds per square inch (PSI) for typically 3-5 minutes. Advantages. Maintains a beverage's taste, color ... If You Are Using HPP Pasteurization, the Pressure ... - Overnight Labels To reduce contamination in the packaging process, products that go through HPP are packed, sealed, and labeled before they go through high pressure processing. Therefore, this has numerous considerations when choosing a label: It's important to select a material that can withstand this pressure and perform in a wet environment. HID® High Temperature Label - HID Global RFID Technology | HID Global They are especially useful for tracking both work-in-progress and finished goods for: industrial tools, medical trays, heavy equipment, car and aerospace components, cargo containers, and even blade and rack servers. Key Features High heat - endures up to 446° F (230° C) Impermeable - repels fire, moisture, oils, petroleum and salt mist WEBINAR: High Pressure Processing (HPP) Products - Safe, Clean-label ... HPP is known as a non-thermal preservation technique that uses water at cold or room temperature (4-25°C) to generate pressure levels up to 6,000 bar (87,000 psi / 600 MPa) to eliminate harmful and spoilage microorganisms, ultimately reducing or eliminating the need for chemical preservatives, while also extending the product shelf-life.

Trader Joe's Cold Pressed Juice More Processed Than Label Suggests ... The lawsuit alleges, however, that Trader Joe's cold pressed juices are more highly processed than consumers expect given they are subject to "a cold water pressure method called HHP (high pressure processing)," as stated on the products' labels. Labels and Tags for Metal Manufacturing - Polyonics Label and Tag Materials For Metals - Forged Under Fire. The HIGHdegree line is rated up to 1112°F (600 °C). Throughout the metal manufacturing process, labels or tags may be applied directly to or hung from the following metal products: Coils Rolls Bars Sheets Rebar Tubes Wire bundles Superior Durability and Quality Label and Tag Materials New 'high pressure certified' seal to hit stores in the next 90 days The Cold Pressure Council - which launched in April 2017 - is developing best practices for the high pressure processing (HPP) industry and the new High Pressure Certified seal. The council ... HPP - High Pressure Processing Solutions | FoodTech - JBT HPP - High-Pressure Processing Solutions Find an HPP Tolling Center Making the most flavorful, freshest, and safest food possible High-Pressure Processing, A Winning Choice HPP, a cold pasteurization technique, is extremely effective. It leverages ultra-high pressure purified water to inactivate bacteria - like listeria, E. coli, and salmonella.

Ultra High Temp Labels • Pres-On Ultra High Temp Labels. Specifically designed to withstand long-term exposure to high temperature processing (autoclave), Pres-On Ultra High Temp Labels are a premium performance, ultra removable, acrylic adhesive coated label stock. Ultra High Temp Labels are compatible with thermal transfer printing processes (100% resin ribbon required) and ...

Labels and Film-Tapes for High Temperature Applications - AI Technology ... The polymeric based labeling films are clean-room compatible. AIT PSAL-300W and PSAL-300R pressure-sensitive labels are engineered for clean-room and electronic applications that provide instant bonding as applied and withstand processing exposure up to 300°C.

Pressure Sensitive Labels | Lomont IMT We offer stocking programs with aggregate minimums, as well as online ordering with pick-and-pack service. Order online today, or call 800-776-0380 to place your order for standard or custom pressure sensitive labels. Contact Lomont IMT today for more information on these or any of our high quality safety products.

Functional Labels | MCC Label This added functionality could be: the ability to fit more information on a small surface, resealable labels to maintain product freshness, Braille printing to fulfill regulatory requirements, interactive packaging for consumer engagement, or hanging labels for promotional purposes. Whatever the need may be, MCC has a solution for you.

Using HPP to produce clean-label raw pet foods High-pressure processing (HPP) is a proven means of creating a safe, clean-label raw pet food, according to Mark Duffy, CEO of Universal Pure, and Aaron Grimm, chief operating officer of Nature's Variety, speaking at Petfood Forum 2018 on April 24.

The Cold-Pressed Truth: What Juice Drinkers Need to Know According to Balasubramaniam, HPP has been used in the United States since the mid-90s, when companies began using intense pressure (sometimes up to 120,000 pounds per square inch, or 10 times greater than the pressure at the bottom of the deepest ocean) to preserve guacamole, vegetable purees, meats and seafood.

Verification Activities for High Pressure Processing, Irradiation and ... FSIS Directive 6120.2, High Pressure Processing (HPP) and Inspection Program Personnel (IPP) Verification Responsibilities, 5/23/12. ... C. IPP are to perform a General Labeling task to review records or observe labels to verify that the establishment has met general labeling requirements including those found in 9 CFR 424.22(c)(4). IPP are to:

High Pressure Processing (HPP) Advantages - Hiperbaric High Pressure Processing (HPP) also known as high pressure pascalization or cold pasteurization is a non-thermal (5ºC - 20ºC) food and beverage preservation method that guarantees food safety and achieves an increased shelf life, while maintaining the optimum attributes of fresh products.

Universal Pure | Your One-Stop HPP Service Provider The Benefits of High Pressure Processing (HPP) Brief is a great resource to learn how HPP can help food & beverage manufacturers, retailers, and food service companies to drive food safety, enable cleaner labels, enhance quality and extend the shelf-life of products. Learn More

Are You Following the HPP Juice Label Laws? In 2015, the U.S. Food and Drug Administration (FDA) has ruled that using the word "fresh" on a HPP juice label is unlawful. Although it's freshly pressed, as soon as you put the juice under pressure, it loses the ability to stake a claim as "fresh" on the label. …. Unless the Juice is Pasteurized.

Health-Based a Top Trend in High Pressure Processing Health-Based a Top Trend in High Pressure Processing HPP touches on the better-for-you and clean-label consumer trends, as well as sustainably utilizing perishable produce, and the growing pet food market. Kim Overstreet Director, Emerging Brands Alliance Oct 4th, 2021 HPP aligns with consumer health trends Getty

High Pressure Processing (HPP) | MCC Label MCC has created a label that can inform the consumer whether or not the product has been protected by HPP technology. Once activated by pressure, the check mark appears and the ink color change is irreversible. Key features Durable label that can actively verify that the product has undergone the pressurization process Possibility of high opacity

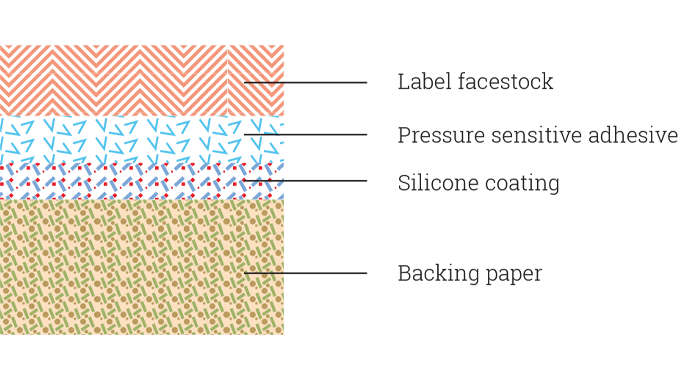

Pressure-sensitive adhesive technologies | Labels & Labeling Pressure-sensitive label adhesives successfully meet an enormous range of demands. They can provide a permanent bond or can be removable. ... That will, for sure, deliver higher shear values, but the downside is that the viscosity of the material becomes so high that processing equipment will no longer properly work. So there is a trade-off ...

HIGHdegree Materials - Tags and Labels for Inventory ... - Polyonics Polyonics Offers High-Temperature Tags and Labels for Extreme Track and Trace Applications in Metals Processing Factories Westmoreland, NH, January 13, 2021 - Polyonics®, a leader in high temperature and harsh environment label and tag materials, announced today a new line of materials specially engineered to stand up to the punishing ...

Post a Comment for "40 high pressure processing labels"